Knowledge Base

- Home

- /

- Knowledge Base

- /

- Benefits & Summary of...

Benefits & Summary of Magnetic Drive Pumps

Benefits:

ZERO LEAKAGE, 100 % EMISSION FREE: Totally Magnetically sealed assembly (No dynamic Seals)

NO SHAFT SEAL / NO PACKING: Since there are no mechanical seal or packing, thereby, reducing MTBF cost.

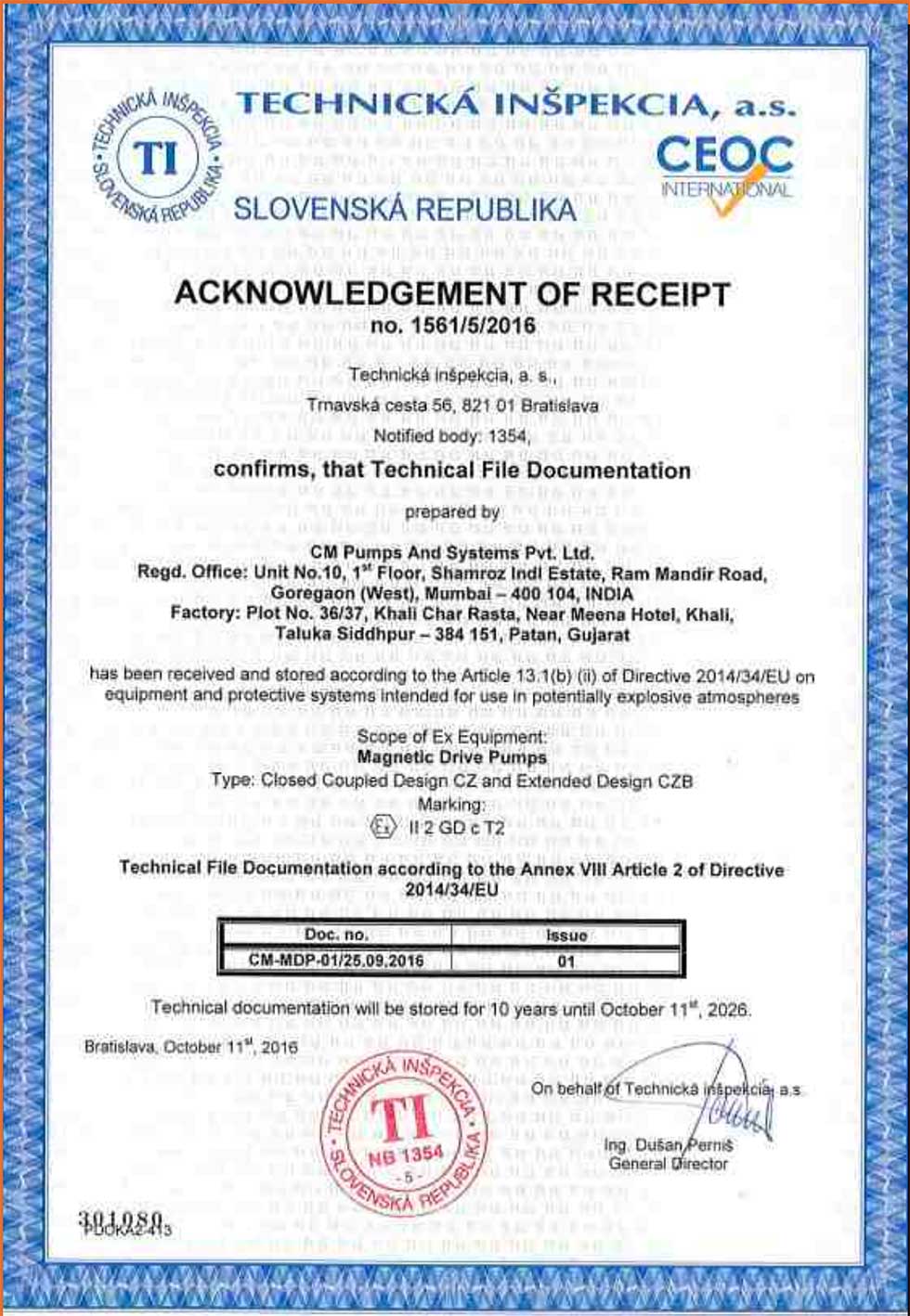

EXPLOSION PROOF: ATEX Certification No. 1561/5/2016

ISO STANDARD: Pump Casing According to ISO 2858 standard and ANSI/ASME B73.1 Standard

NO EXTERNAL LUBRICATION: Pumped fluid provides cooling and thin film lubrication to bearing and Can Shell. No lubrication levels to check or maintain.

ALL PUMPS PERFORMANCE TESTED: CM Pumps adhere to strict statistical quality control tolerance and each pump and motors are 100% performance tested before dispatch.

AFTER SALES SERVICE: All wear parts are easily repaired / replaced.

SAFETY OPTIONS: To achieve the optimum protection for CM Pumps against contingent failures, protection devices like Auto Leak Detector , Auto Electrical cut off when Temp of can shell increase. Or we can give Double Can with pump.

Summary:

Advances in pump technology have enabled engineers to reduce the size of magnetic drive pumps whilst increasing their power and efficiency. Rare earth alloy magnets with high field strength allow compact design. New pump bearing designs and a wide range of wetted material options have enhanced pump lifetime, lowered power losses due to eddy currents and reduced maintenance downtime

Different designs of magnetic drive pumps are available including centrifugal pumps, side channel pumps, turbine pumps, vane pumps and internal and external gear pumps. Magnetic drive pumps can be specified for applications where self-priming or handling solids or running dry is required and are often specified for pumping difficult liquids such as abrasive liquids, acids, bases, corrosives, flammables, inorganic solutions, liquids with entrained gases, organic liquids, slurries, solvents, toxic liquids, viscous and volatile liquids. Magnetic drive pumps are available for a wide range of viscosities at high and low temperatures at capacities from ml/hr to m³/min and for high system pressures and high differential pressures.

All these different designs of magnet drive pumps offer the key benefit of zero leakage of the pumped medium.