Knowledge Base

- Home

- /

- Knowledge Base

- /

- How do magnetic drive...

How do magnetic drive pumps work?

Bearings for magnetic drive pumps:-

Because a magnetic drive pump is an enclosed piece of equipment, lubrication oil or grease cannot be used for bearings. Therefore, pumped liquid is used for the lubrication of bearings as well as for cooling needs. A portion of pumped liquid is usually taken from the discharge of the pump; this flow is often known as recirculation flow and is usually employed for the cooling of the magnetic system, lubrication of radial and thrust bearings and for other similar applications where lubricant or cooling fluid is needed.

Magnet drive pumps are usually equipped with “sleeve bearings,” which use the pumped liquid for hydrodynamic lubrication. A sleeve bearing is one of the simplest types of bearing, comprising just bearing surfaces and no rolling elements. Therefore, the sleeve or journal slides over the bearing surface where pumped liquid is used for its lubrication. These bearings are also compact and lightweight and have a high load-carrying capacity and longer life compared to many rolling-element bearings. The materials of construction of these and the required clearances of the sliding surfaces may restrict the liquids and services for which this kind of pump may be used.

Traditionally, magnetic drive pump bearings have been made from silicon carbide, which has been an excellent bearing material under normal operation; however, it can suffer during some abnormal conditions such as dry running, dynamic loading and potential impact. Some modern materials such as advanced ceramics have been used in these with great success. Another proposed material is a fiber-reinforced silicon carbide ceramic composite with bearing properties similar to silicon carbide, but with high impact resistance and excellent tolerance of dry running. These modern options offer great benefits such as better impact resistance, excellent wear resistance and generally longer life and better performance.

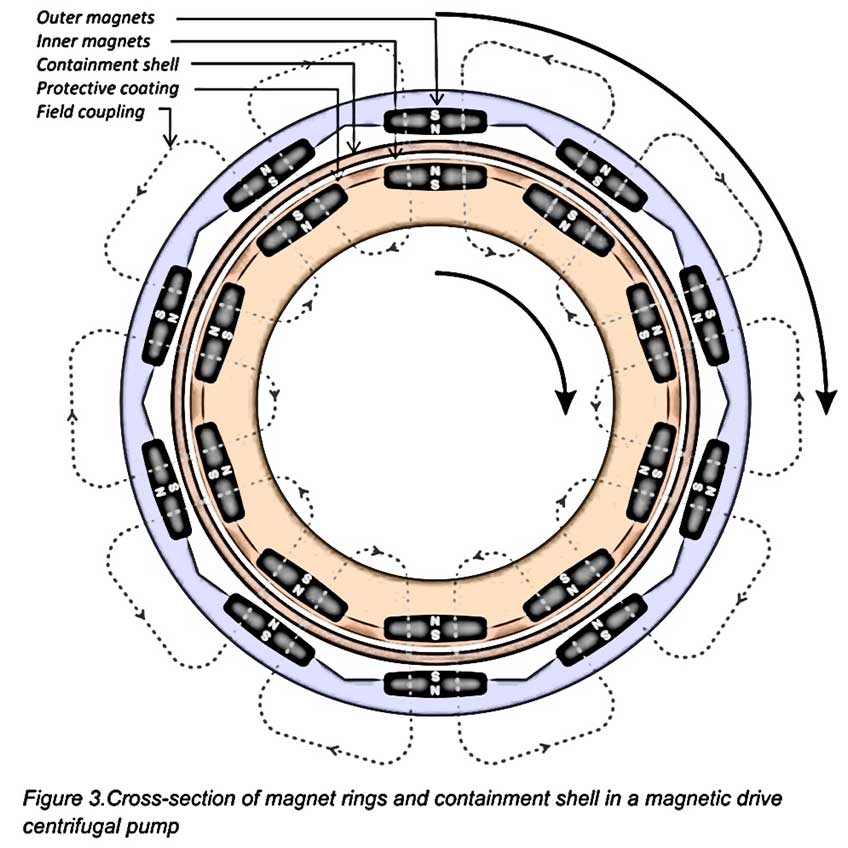

The use of these materials is a major factor in the cost of magnetic drive pumps. Most rare earth metals are mined in only a few places around the World (notably China) and prices can be volatile. For example, China manufactures 76% of the World’s Neodymium magnets. Apart from their cost, another disadvantage of these alloys is their poor resistance to corrosion. It is necessary to coat the magnets on the inner ring (which are exposed to the pumped fluid) with some form of protective resin or enclose them in a corrosion resistant casing, for example polypropylene, PVDF (poly vinylidene fluoride), ETFE or stainless

The maximum torque that can be achieved in a magnetic drive pump is determined by the gap between the magnets: the smaller the gap the larger the torque transfer. However, there is a limit to how small this can be engineered, since the gap must include the containment shell and any protective materials coating the magnets. For the safe operation of the pump, it is important that there is a reasonable gap between the rotating parts and the containment shell, especially if the pumped fluid is highly viscous or contains solids. All parts must therefore be machined to high tolerances for greatest efficiency. In addition to these engineering concerns, the material used in the construction of the containment shell is important in maintaining a high coupling efficiency between the two sets of magnets and in reducing power losses due to the generation of eddy currents.

The inner magnet ring, the pump shaft and its bearing are immersed in the pumped fluid and lubricated by it. It is important that these parts are designed to operate efficiently in the environment. With highly viscous liquids, friction losses can be high; in an abrasive or chemically aggressive medium, bearing wear can be a problem. However, with the right choice of wetted materials – including silicon carbide, thermoplastics, stainless steel and high nickel alloys – magnet drive pumps are ideal for handling aggressive, corrosive and hazardous liquids.