Knowledge Base

- Home

- /

- Knowledge Base

- /

- Why Standard Centrifugal...

Why? Standard Centrifugal Pump

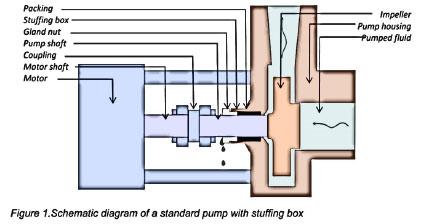

With a standard centrifugal pump, some form of seal is necessary to stop the pumped medium from leaking out around the pump shaft, especially if it is at high pressure. There are three main options:

A soft packing material compressed around the pump shaft in a ‘stuffing box’ Packing material is held in place within the opening in the casing (the stuffing box) and compressed by a gland nut which can be progressively tightened as the packing material wears or settles .

Lip seal or O-ring A rubber or plastic ring fits around the drive shaft and is held in place in a recess in the pump housing.

Mechanical seal consists of two parts: a stationary component attached to the pump housing and a rotating component on the pump shaft. The faces of the two components are machined to be flat and smooth and are spring-loaded to keep them pressed together. This is the most effective option for reducing leaks but can be expensive and difficult to set up.