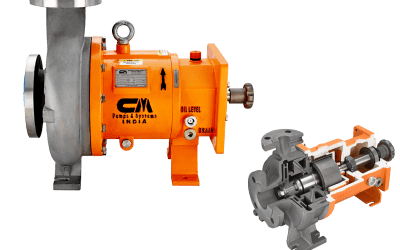

Magnetic drive pumps are typically used where leakage of the pumped liquid poses a great risk such as with aggressive or risky liquids, exotic materials, acids, alkalis, corrosives, pollutants and toxics. They are also used for ultra-pure liquids and hard-to-seal liquids.

Knowledge Base

- Home

- /

- Knowledge Base

When and why would I need MAG DRIVE PUMP?

Generally when the product being pumped is of a corrosive nature, or the leakage of that product has the potential to harm operators or cause damage to the environment.

Why Standard Centrifugal Pump?

Knowledge BaseLeakage cannot be eliminated completely with any of these solutions and, in fact, it is important to maintain a small leakage to lubricate and cool the seal and pump shaft. In some cases, it is necessary to inject a lubricant to avoid...

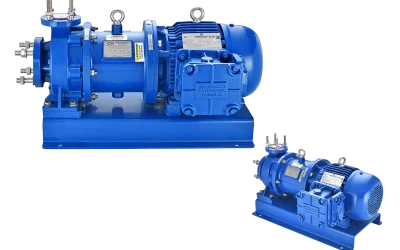

Why are magnetic drive pumps used?

Knowledge BaseA pump seal requires monitoring and frequent maintenance to avoid excessive leakage, particularly when the pumped fluid contains abrasives. All leaked fluids have to be contained and disposed of safely. If the fluid is also toxic,...

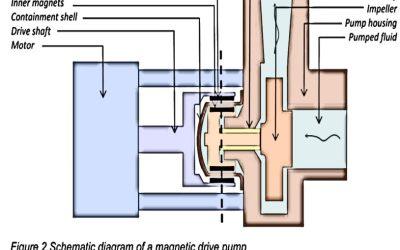

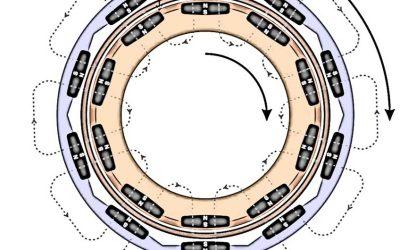

How do magnetic drive pumps work?

Knowledge BaseBearings for magnetic drive pumps:-Because a magnetic drive pump is an enclosed piece of equipment, lubrication oil or grease cannot be used for bearings. Therefore, pumped liquid is used for the lubrication of bearings as well as for...

Magnetic drive pumps for liquid containing solids

Knowledge BaseMagnetic drive pumps have very limited solids handling capability. The pumped liquid should be clean or else the solids will collect in the passages surrounding the magnet and in the close tolerances of bearings such as between the...

Benefits & Summary of Magnetic Drive Pumps

Knowledge BaseBenefits:ZERO LEAKAGE, 100 % EMISSION FREE: Totally Magnetically sealed assembly (No dynamic Seals)NO SHAFT SEAL / NO PACKING: Since there are no mechanical seal or packing, thereby, reducing MTBF cost. EXPLOSION PROOF: ATEX...